Sutton Leisure Centre

316 malden Road

North Cheam

Surrey SM3 8EP

Today

Published material

Baths & Bath Engineering Editor Jenkyn Griffiths B.Sc P.A.Inst.W.E. May 1938 No.51 Vol. 5 p91 – 97

Sutton and Cheam’s Public Baths

Sutton and Cheam’s Public Baths

MODERN BUILDING IN MALDEN ROAD, CHEAM

EVEN at first sight the new baths opened by the Mayor, Ald. Grahame R. Glegg, J.P., in Malden road, Cheam, on April 9. make it apparent that success has attended the enterprise of the borough engineer and surveyor of Sutton and Cheam, Mr. N. H. Michell, Assoc.M.Inst.C.E., chartered civil engineer and registered architect, who designed and supervised the erection of the building, assisted by Mr. T. Wilson and Mr. H. Thornley, of his department. The preliminary sketch plans were prepared by Mr. W. Hedley Grieves, who retired from the position of engineer and surveyor in 1934.

Erected at a cost of about £33,393, exclusive of land and furniture the building is primarily designed as a swimming bath, but is convertible into a public hall during the winter months.

The entrance hall contains the ticket office and gives access to the main hall and swimming bath, the male and female waiting roams and dressing rooms, cafe, administrative offices, .md to the two staircases leading to the balcony.

The entrance hall contains the ticket office and gives access to the main hall and swimming bath, the male and female waiting roams and dressing rooms, cafe, administrative offices, .md to the two staircases leading to the balcony.

Ticket Office

In this office the machines comprise six four-way ticket cabinet and issuers, one six-way operated ticket issuing machine, and one keyboard coinometer.

The ticket cabinet’ and issuer gives all the essentials of revenue security and sales analysis present in the larger type of ticket registers, but, as the issuing mechanism is reduced to a minimum, speed of issue is not a feature. Ticket issuing mechanisms are at the cashier’s side of the machine, and are operated by pressing against the ticket plate with the finger and thumb, grasping the ticket which then protrudes. Issue recording is automatic, the recorders being identical with those of larger ticket registers.

The chromium plated top forms a counter for exchanging tickets and cash.

The ticket issuing machine is one of several standard products designed for revenue collection and control where a, multiplicity of different prices or classifications are not required, but where rapid ticket issue is of primary importance. The machine is specially designed for ticket office location, its flat top plate forming a counter; the manufacturers claim that it is the fastest hand-operated machine in existence, issuing any quantity of tickets from one to five by the simple movement of an operating lever.

It is constructed on the unit principle, each unit having a separate issuing and recording mechanism, and an irreversible, untamperable numerical recorder to check the issue of tickets through the unit, these being of a type acceptable to H.M. Customs and Excise for computation of entertainment tax. To prevent unauthorised ticket issue a lock is provided, and the magazines can be replenished when the issuing mechanisms are locked or unlocked.

The keyboard coinometer is, it is claimed, the fastest change-giver in existence, and has no working parts to get out of order. It is, therefore, most useful to both large and small baths, since it speeds up the operation of change giving. The machine consists of one row of tubes, which hold the various coins, and the cashier has only to press one of the keys marked with shillings and pence in the two rows and the money slides into the delivery cup automatically. The coins received from the customer are placed into the tubes again for further use.

Swimming Bath

Complying with the requirements of the Amateur Swimming Association, the swimming bath is 100 ft. long by 42 ft. wide, and the depth of water ranges from 3 ft. to 6 ft., with a diving pit 9 ft. 6 in. deep. The diving stage has fixed and spring boards at heights of 1 m. and 3 m., and a 5 m. fixed board, all to A.D.A. specification. The access ladders to the bath are also to this specification.

Complying with the requirements of the Amateur Swimming Association, the swimming bath is 100 ft. long by 42 ft. wide, and the depth of water ranges from 3 ft. to 6 ft., with a diving pit 9 ft. 6 in. deep. The diving stage has fixed and spring boards at heights of 1 m. and 3 m., and a 5 m. fixed board, all to A.D.A. specification. The access ladders to the bath are also to this specification.

The bath is lined with “Batco” precast polished slabs in white Snowcrete ” mixture, 2 ft. 3 in. by 1 ft. 6 in. by 2 in, thick, with precast polished “Batco” tiles, in black, 9 in. by 3-in., to form swimming lines. All slabs were manufactured with grooved edges. The scum channel is also in “Batco” precast polished white units 12 in. by 9 in. The coping slabs in cream are supplied with serrations, and slightly roughened surface to prevent possibility of slipping. “Batco” 12 in. by 12 in. tiles in a lighter cream are used for the surround, and these are also treated to prevent slipping.

For the underwater lighting eighteen 500 watt projectors are used equipped with special prismatic reflectors. Around the bath a number of cast bronze built-in units are installed for lighting the floor. These built-in units are equipped with 60 watt lamps.

Filtration and Sterilisation Plant

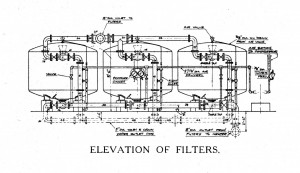

The plant for the continuous circulation and filtration of the swimming bath water is capable of dealing with 38,210 gal, per hour, giving a complete circulation of the whole of the contents of the bath once every four hours. The plant comprises : Electrically driven pumps, shunt feed chemical apparatus, vertical type air scoured pressure filters, compressor and motor, and the necessary circulating piping, connecting the plant to and from the bath, including suction grid and frame built into the deep end of the bath and specially designed “Bell” type inlet, at the shallow end of the bath. The installation also includes a chlorination apparatus for the sterilisation of the water.

The plant for the continuous circulation and filtration of the swimming bath water is capable of dealing with 38,210 gal, per hour, giving a complete circulation of the whole of the contents of the bath once every four hours. The plant comprises : Electrically driven pumps, shunt feed chemical apparatus, vertical type air scoured pressure filters, compressor and motor, and the necessary circulating piping, connecting the plant to and from the bath, including suction grid and frame built into the deep end of the bath and specially designed “Bell” type inlet, at the shallow end of the bath. The installation also includes a chlorination apparatus for the sterilisation of the water.

The cycle of the operation of the plant is as follows:- -The pumps draw the water from the deep end of the bath, and it first of all passes through the strainer box. The necessary chemicals are then added to the water by means of the chemical apparatus provided. The coagulation consists of hydrated almnina.

The cycle of the operation of the plant is as follows:- -The pumps draw the water from the deep end of the bath, and it first of all passes through the strainer box. The necessary chemicals are then added to the water by means of the chemical apparatus provided. The coagulation consists of hydrated almnina.

Before being returned to the shallow end of the bath the water is chlorinated and is also passed through the heater which maintains the temperature at 74 deg. Fahr.

Washing of the filter is carried out by means of a reverse flow of water, and the breaking up of the filter bed by compressed air.

The sterilising apparatus consists of a W&T chlorinator type BDPIM and a W&T ammoniator type BDPAM. The general principle of operation of the chlorinator is described as semi-vacuum, chlorine gas being metered under pressure as reduced by the control valve, by drawing into an injector by vacuum produced by the passage of a stream of water. This principle is for ensuring accuracy, long life and ample safeguard against gas leaks, and operation of the unit is extremelysimple. The ammoniator is characterised by the same high standard of design, workmanship and materials as the W&T chlorine equipment. Manipulation of only one valve enables more or less gas to be added to the water at will, whilst there is ample protection against corrosion and leakages.

The sterilising apparatus consists of a W&T chlorinator type BDPIM and a W&T ammoniator type BDPAM. The general principle of operation of the chlorinator is described as semi-vacuum, chlorine gas being metered under pressure as reduced by the control valve, by drawing into an injector by vacuum produced by the passage of a stream of water. This principle is for ensuring accuracy, long life and ample safeguard against gas leaks, and operation of the unit is extremelysimple. The ammoniator is characterised by the same high standard of design, workmanship and materials as the W&T chlorine equipment. Manipulation of only one valve enables more or less gas to be added to the water at will, whilst there is ample protection against corrosion and leakages.

Dressing Accommodation

The dressing rooms are two in number and provide 28 Plymax standard dressing cubicles- for each sex. Plymax is plywood faced with metal and the material is particularly resistant to damp conditions and damage. In this instance the metal used is steel subsequently painted. Provision is made for 312 bathers, the lockers accommodating the well-known “Hyg-gard-all” compact clothes hangers.

The dressing rooms are two in number and provide 28 Plymax standard dressing cubicles- for each sex. Plymax is plywood faced with metal and the material is particularly resistant to damp conditions and damage. In this instance the metal used is steel subsequently painted. Provision is made for 312 bathers, the lockers accommodating the well-known “Hyg-gard-all” compact clothes hangers.

Towel chutes in the dressing rooms discharge into baskets in the subway under the bath surround. The subway communicates with the laundry and obviates the necessity for wheeling soiled towels, costumes, etc., along the bath surrounds and corridors.

Access to the swimming bath from the dressing rooms can only be obtained by the bathers passing through foot baths.

Heating and Ventilation Plant

Direct heating apparatus of the low pressure accelerated hot water system is provided, with the mains in the subway under the, bath surround, and radiators distributed round the building.

Direct heating apparatus of the low pressure accelerated hot water system is provided, with the mains in the subway under the, bath surround, and radiators distributed round the building.

Hot water supply is served indirectly from the boilers through a storage calorifier and a circulating pump is fitted on the secondary circulations which are carried to within a few feet of each point of draw-off.

In connection with the heating plant two 3 in. pumps and one 1 in. pump are installed. These pumps are of the end suction single-stage type. The impellers, which are hydraulically and mechanically balanced are cast in special bronze, and the shaft, which is of stainless steel is carried in a long and substantial journal bush bearing.

The large hall has plenum and extract ventilation. The plenum plant consists of a centrifugal cased fan which draws fresh air from the outside through dry throw-away type filters. This air passes through a heating battery and is blown into the hall under the balcony at one end. A propeller extract, fan is fitted in the roof to extract air through ceiling gratings at the other end. These fans are controlled by interlocked switchgear.

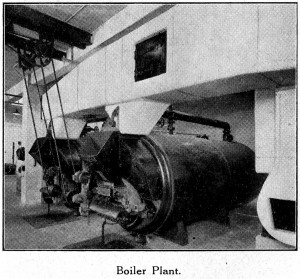

The boiler plant consists of two “Economic” independent hot –water boilers 10 ft. 6 in. long by 5 ft. 9 in. diameter, fired by automatic stokers. An induced draught fan is fitted on the smoke outlet. These boilers serve the heating apparatus, hot water supply calorifier, plenum heating battery and the swimming bath water heater.

With the automatic smokeless and gritless coking stokers, each having a self-cleaning furnace, the fuel is all fed on through a hopper to the front of the furnace, where the heavy volatile matter is driven off, and in passing over the incandescent portion of the fire bed is consumed. The fuel is then slowly carried along the moving grate, the fire bed reducing in thickness as its travel advances, and by the time the back end of the bars is reached only burnt out clinker and ash remains, which is deposited over the end of the grate into an ashpit from whence it is removed underneath the bars by firing tools provided for that purpose. The stokers can be regulated to deal with the varying loads.

Laundry

This comprises a rotary washer, soap boiler, hydro-extractor, washing trough, mangling machine and four draw-out drying cupboards. A 6 h.p. electric motor drives the machines through shafting, pulleys and belting.

The unit which is used for supplying steam to the laundry equipment is a controlled flame boiler working at a pressure of 60 lb. per sq. in. The gas is automatically

General

Accommodation for 262 spectators is provided in the balcony. When used as a public hell, the swimming bath and surrounds will be covered with a portable spring floor, and accommodation will be provided for seating 884 persons on the ground floor, making a total seating capacity of 1.146.

Accommodation for 262 spectators is provided in the balcony. When used as a public hell, the swimming bath and surrounds will be covered with a portable spring floor, and accommodation will be provided for seating 884 persons on the ground floor, making a total seating capacity of 1.146.

The stage is 42 ft. 6 in. by 22 ft. and is fitted with a fireproof roller shutter and the usual stage lighting designed to comply with the regulations of the licensing authority.

The artificial lighting in the main hall is diffused from the roof space through lay-lights in the ceiling. These are illuminated by forty-two 500 watt reflectors.

Amplifier Installation – Provision has been made for speech and music relay when the bath is converted into a public hall. The equipment is primarily designed to function in the building when a floor is laid down, although tests of speech and music have proved satisfactory under swimming bath conditions. The equipment consists of two two-stage power amplifiers, having high fidelity response and an undistorted output of 15 watts each. These are fitted with pilot light, mains switch, volume control and output test point on the front panels. The operating board consists of one two-way microphone fader and amplifier for use with microphones, one output panel fitted with four D.P.D.T. lever switches and loudspeaker circuits, and one projecting type single turntable assembly complete with pickup, output of which is regulated by master control on microphone amplifier. The microphone L.T. is fitted at the rear of the mains input panel. The whole is mounted on a light gauge rack approximately 5 ft. high and finished in service grey, and occupies space about 3 ft. by 4 ft.

The installation is located in the lighting control room. An interesting feature is the position of the speakers. Altogether there are 10 senior elliptical magnet moving coil loudspeaker units, six of which are built into the roof of the bath hall, and for operating purposes these are grouped laterally in banks of two. In addition there are two sets of coupled speakers built into the proscenium arches and these face outward towards the auditorium. In operation the proscenium arch speakers are coupled so that one switch controls four speakers whereas the roof speakers are controlled in groups of two only. The whole of the equipment is of Marconi-E.M.I. manufacture.

The installation is located in the lighting control room. An interesting feature is the position of the speakers. Altogether there are 10 senior elliptical magnet moving coil loudspeaker units, six of which are built into the roof of the bath hall, and for operating purposes these are grouped laterally in banks of two. In addition there are two sets of coupled speakers built into the proscenium arches and these face outward towards the auditorium. In operation the proscenium arch speakers are coupled so that one switch controls four speakers whereas the roof speakers are controlled in groups of two only. The whole of the equipment is of Marconi-E.M.I. manufacture.

Wall Tiling and Terrazzo Work.-The wall tiling to the bath hall is of the new unit size, 12 in. by 8 in., in a mottled glaze with eggshell finish, with features such as curved columns and frieze relief formed in small tile strips. The columns are treated in a range of graduated colours.

The terrazzo work comprises:-Crush hall, staircases, halls and waiting rooms and corridors in situ buff terrazzo paving sectionised with brass dividing strips, to form panels ranging from 3 ft. to 4 ft. sq., and green terrazzo moulded and coned skirting; lavatories-grey terrazzo paving with green cooed skirting ; showers-inn situ green terrazzo paving and wall lining ; No. 2 staircases -in situ buff terrazzo treads and risers with moulded nosings with green and white chequer pattern alundum non-slip inset to treads, and in, situ green terrazzo wall lining with green skirting.

Mr. F. Swinnerton, M.N.A.B.S., is the superintendent of the baths.

Contractors.

Messrs. Burnard and Pickett, of Wallington, were the main contractors for the building and amongst the specialist firms engaged were : – Adamsez. Ltd.; sanitary- fittings; Alpha Manufacturing and Electrical Co., Ltd., electrical installation; Automaticket, Ltd., ticket office machines; Bell Bros. (Manchester 1921), Ltd., filtration plant; Bradford, Thos., and Co., laundry plant; British Art Tile Co., Ltd., tiling to bath and surrounds; British Reinforced Concrete Co., consulting engineers for reinforced concrete work; Bullough Bros., amplifier installation; Carter and Co. (London), Ltd., wall tiling to bath hall; Caxton Floors, Ltd., hollow tile floors; Chloride Electrical Storage Co., Ltd., emergency lighting plant; Comyn, Ching and Co. (Lend.), Ltd., ironmongery ; Controlled Flame Boilers, Ltd., steam unit for laundry– equipment ; Crittall Manufacturing Co., Ltd., metal windows. laylights, and leaded lights; Dennison, Kett and Co.. Ltd., roller shutters; Diespeker and Co., Ltd., terrazzo work: Direct Spray Process Co.. Ltd., painting ; French Asphalte Co.. Ltd., asphalt; General Electric Co., Ltd.. electric light fittings; Haden, G. N., and Sons, Ltd.. hunting and ventilation, and laundry- installation ; Hay-wards, Ltd.; diving stage, spring board and access ladders to bath ; Hodgkinson. James (Salford), Ltd., automatic coking stokers; Holden and Brooke, Ltd., pumps for heating plant; Holophane, Ltd., underwater floodlights; Honeywill and Stein, Ltd., acoustic plaster; -Morton, Jun., Francis and Co., temporary winter floor ; Nobel Chemical Finishes, Ltd., paints ; Noble, A., plastering ; Palmer, T. W. and Co., wrought iron metal work ; Patent Victoria Stone Co., reconstructed stone; Pel, Ltd., nesting chairs with grey enamelled frames and red upholstered seats; Redpath. Brown and Co., Ltd., steelwork ; Sieber, James, “Hyg-gard-all” clothes hangers ; Spiller, E., and Sons, plumbing ;Turner, W., and Co., Ltd., balcony seating; Universal Asbestos Manufacturing Co., Ltd., asbestos roofing ; Venesta, Ltd., flush doors and dressing cubicles; Wallace and Tiernan, Ltd., bath water sterilising apparatus.

Do you have a record of who performed at the Baths on the evening of 15 December 1961?

Excellent article, has just aided greatly in a family discussion!

Pleased we were able to help. If you can add to our information please email. Best wishes Carl